Mexico City's Evolution: Dreams of Fiber, Earth, and Concrete

- October 19, 2022

- By: Editorial Team

- NEWS

An architectural installation called Dreams of Fiber/Timber, Earth, Concrete was featured in the Mextrópoli Architecture and City Festival between September 21-25, 2022. Through the use of four materials, the installation presents stories from Mexico City's past and present. By utilizing the materials, we are reinterpreting tradition, imagining creative possibilities, and adapting history. Visitors were invited to recall the city's history through the installation.

An architectural installation called Dreams of Fiber/Timber, Earth, Concrete was featured in the Mextrópoli Architecture and City Festival between September 21-25, 2022. Through the use of four materials, the installation presents stories from Mexico City's past and present. By utilizing the materials, we are reinterpreting tradition, imagining creative possibilities, and adapting history. Visitors were invited to recall the city's history through the installation.

Firstly, there is "Dreams of Fiber/Timber," which reflects on the past and future of Mexico City. La Feria's Montana Rusa and pavilion were constructed using wood materials from the city's iconic rollercoaster, papel picado, also known as perforated paper or pecked paper. It was an invitation to the ancestors to pass on to the present. The Montana Rusa remained open until 2019 and is remembered by millions of people around the world. This roller coaster captured the era of massive socio-economic changes and civic infrastructure development in Mexico City, similar to other large-scale urban projects built during the same decade. This pavilion is located on the corner of the historic Plaza de la Alameda, creating a new urban space for meeting and reflection. Through dialogues with the Otomi artisans who make the amate paper for the pavilion, the pavilion's lighting design activates the space at night.

Firstly, there is "Dreams of Fiber/Timber," which reflects on the past and future of Mexico City. La Feria's Montana Rusa and pavilion were constructed using wood materials from the city's iconic rollercoaster, papel picado, also known as perforated paper or pecked paper. It was an invitation to the ancestors to pass on to the present. The Montana Rusa remained open until 2019 and is remembered by millions of people around the world. This roller coaster captured the era of massive socio-economic changes and civic infrastructure development in Mexico City, similar to other large-scale urban projects built during the same decade. This pavilion is located on the corner of the historic Plaza de la Alameda, creating a new urban space for meeting and reflection. Through dialogues with the Otomi artisans who make the amate paper for the pavilion, the pavilion's lighting design activates the space at night.

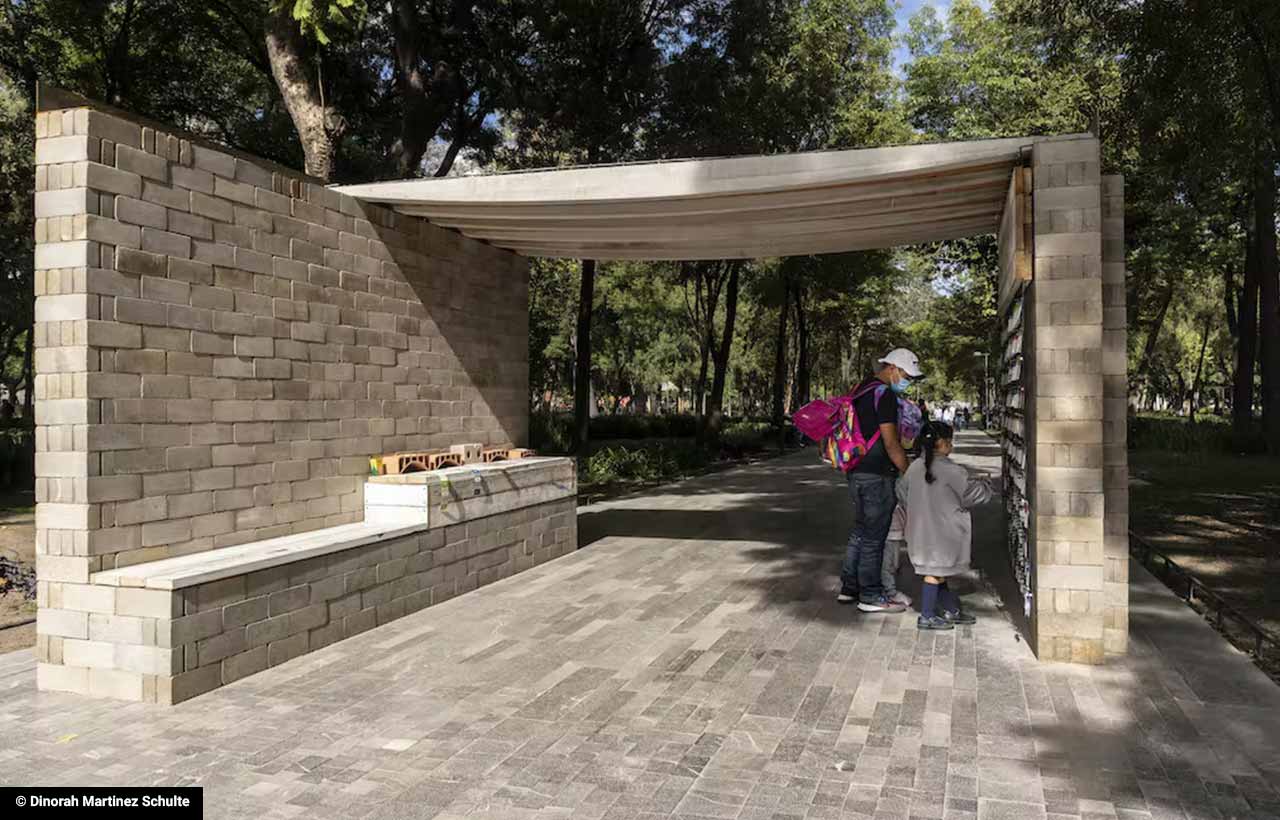

Dreams of Earth/Concrete, the second pavilion, explored Mexico's affordable housing future. Echale, a social enterprise based in Mexico that offers housing solutions through the integrated development of communities, partnered with New Story to implement the pavilion. New Story pioneers solutions to end global homelessness.

Three-dimensional ceramic vaults are used to create Dreams of Earth, which are created in CDMX using local materials. The upper compression slab is formed by these forms placed between precast concrete beams. Using 3D printing, custom ceramic vaults can be mass-produced according to the materials available. A traditional clay and firing process has been used to produce the blocks in collaboration with local ceramic manufacturers. In order to minimize material consumption and manufacturing time, the blocks are lightweight and optimized. Researchers at MIT developed computational design methods to achieve the elegant geometry created by sections of varying widths and depths. In order to manufacture it, fiberglass molds are used, which allow multiple casting cycles. Using local construction techniques and digital manufacturing technologies, Dreams of Concrete creates a pavilion that combines industry, social enterprise, and academia for a more sustainable built environment.

Three-dimensional ceramic vaults are used to create Dreams of Earth, which are created in CDMX using local materials. The upper compression slab is formed by these forms placed between precast concrete beams. Using 3D printing, custom ceramic vaults can be mass-produced according to the materials available. A traditional clay and firing process has been used to produce the blocks in collaboration with local ceramic manufacturers. In order to minimize material consumption and manufacturing time, the blocks are lightweight and optimized. Researchers at MIT developed computational design methods to achieve the elegant geometry created by sections of varying widths and depths. In order to manufacture it, fiberglass molds are used, which allow multiple casting cycles. Using local construction techniques and digital manufacturing technologies, Dreams of Concrete creates a pavilion that combines industry, social enterprise, and academia for a more sustainable built environment.

Stay updated with the latest trends and developments in architecture, design, home decor, construction technology, and building materials through Building Material Reporter.

Stay updated with the latest trends and developments in architecture, design, home decor, construction technology, and building materials through Building Material Reporter.