Construction Chemicals: Ease for Construction

- January 6, 2023

- By: Editorial Team

- PRODUCTS AND MATERIALS

Modern chemistry has led to the invention of many new chemicals that play an essential role in the construction industry today. Construction chemicals are an integral part of the chemical industry and have changed the ideology of construction greatly since they were introduced. Building materials are enhanced with these chemicals in construction projects to make them durable, sustainable, and economical.

Here are some brief details about construction chemicals and types that are used in the construction industry.

As the name implies, construction chemicals are substances used in construction. There is a wide range of functional applications for these chemicals in the construction industry. Construction projects can be speeded up or new projects can be started to repair and retrofit older buildings, or to add strength and durability to the structures. Various building materials and construction chemicals are used on construction sites to enhance workability, increase efficiency, boost effectiveness, protect parts of structures, or speed up the construction pace.

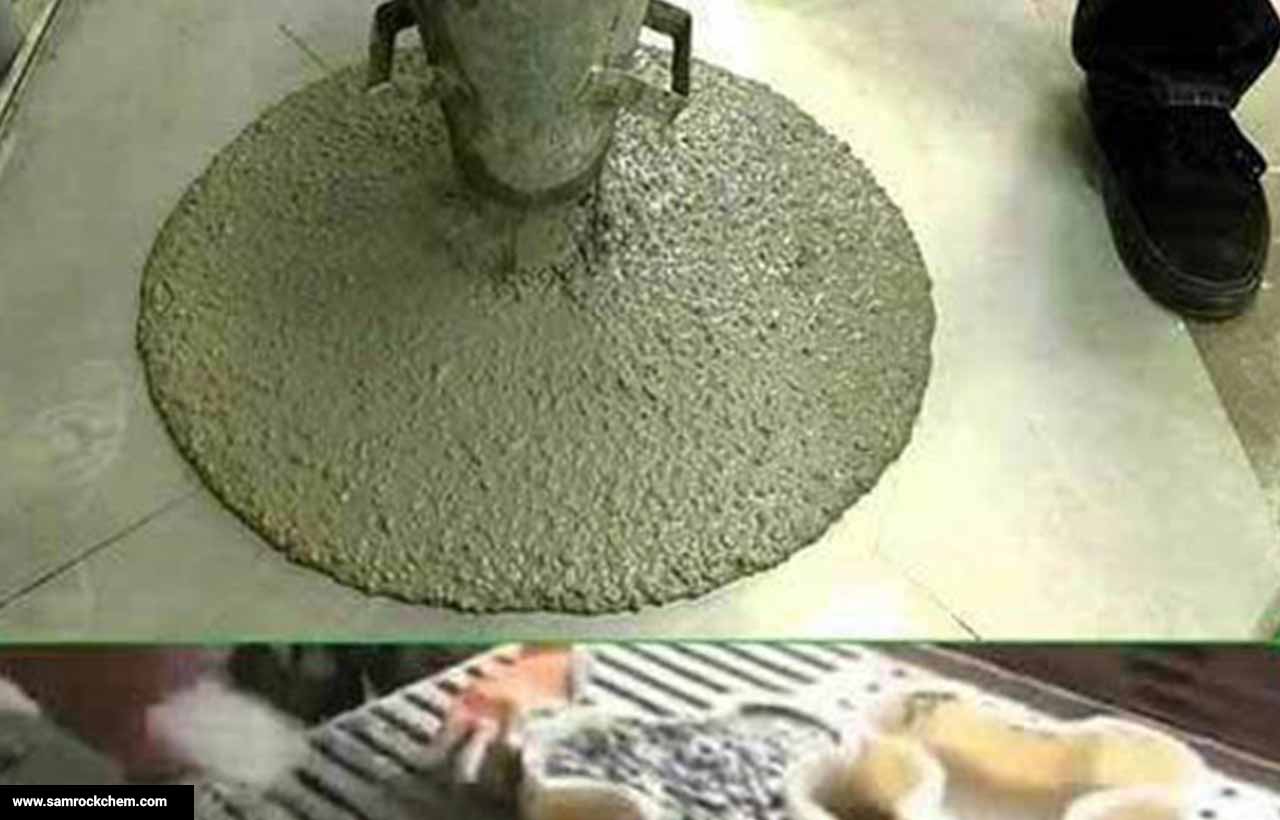

Concrete Admixtures

Presently, concrete is the most popular material for various purposes depending on the site's conditions. Ordinary concrete is modified by admixtures in these types of situations to meet the requirements, thereby making it more suitable. Apart from cement, water, and aggregates, additives are materials that are used in concrete. Immediately before or during mixing, it’s added to the batch. The quality performance or durability of ordinary concrete can be compromised under certain conditions.

Presently, concrete is the most popular material for various purposes depending on the site's conditions. Ordinary concrete is modified by admixtures in these types of situations to meet the requirements, thereby making it more suitable. Apart from cement, water, and aggregates, additives are materials that are used in concrete. Immediately before or during mixing, it’s added to the batch. The quality performance or durability of ordinary concrete can be compromised under certain conditions.

Plasticizers (Water Reducers)

Plasticising admixtures are organic or inorganic substances whose properties permit a reduction in water content for given workability or an increase at the same water content. Both cases offer considerable benefits. As a result of the former, concrete is stronger, while as a result of the latter, it’s easier to work with. Plasticisers consist of anionic surfactants, such as lingo sulphonates, their derivatives, and salts of sulphonates hydrocarbons. Nonionic surfactants, such as polyglycol esters, hydroxylated carboxylic acids, and derivatives of these acids. Plasticisers are primarily used to fluidify concrete, grout, or mortar mixes, decrease friction between particles, and improve their workability.

Plasticising admixtures are organic or inorganic substances whose properties permit a reduction in water content for given workability or an increase at the same water content. Both cases offer considerable benefits. As a result of the former, concrete is stronger, while as a result of the latter, it’s easier to work with. Plasticisers consist of anionic surfactants, such as lingo sulphonates, their derivatives, and salts of sulphonates hydrocarbons. Nonionic surfactants, such as polyglycol esters, hydroxylated carboxylic acids, and derivatives of these acids. Plasticisers are primarily used to fluidify concrete, grout, or mortar mixes, decrease friction between particles, and improve their workability.

Retarders and Retarding Plasticisers

A retarder is an admixture that slows down the chemical process of hydration so that concrete remains plastic and workable for longer periods of time. In hot weather concreting, retarders are used to overcome the accelerating effect of high temperature on setting properties. Many pours can also be cast and consolidated without forming cold joints when using these retarders. A concrete exposed aggregate look can be achieved with retarding admixtures. Calcium sulfate is the most common retarder. Starches, cellulose products, sugars, acids, or acids salts are some of them.

A retarder is an admixture that slows down the chemical process of hydration so that concrete remains plastic and workable for longer periods of time. In hot weather concreting, retarders are used to overcome the accelerating effect of high temperature on setting properties. Many pours can also be cast and consolidated without forming cold joints when using these retarders. A concrete exposed aggregate look can be achieved with retarding admixtures. Calcium sulfate is the most common retarder. Starches, cellulose products, sugars, acids, or acids salts are some of them.

Damp-proofing and Waterproofing Admixtures

Depending on the application, waterproofing admixtures can be powdered, pasted, or liquid. It consists of materials that fill pore spaces or repel water. Pore fillers consist of silicates of soda, aluminum, and zinc sulfates, which are chemically active. Additionally, they speed up the setting time of concrete, which renders it more impervious at an early stage. Chalk, fuller earth, and talc are chemically inactive pore-filling materials. These materials are normally very finely ground. Basically, they make dense concrete impervious and facilitate the reduction of water for a given workability. In this group of admixtures, materials, such as soda, potash soap, calcium soap, resin, vegetable oils, fats, waxes, and coal tar residues are added as water repellants. It’s common to add calcium or ammonium stearate and calcium chloride along with inorganic salts of fatty acids in some waterproofing admixtures.

Depending on the application, waterproofing admixtures can be powdered, pasted, or liquid. It consists of materials that fill pore spaces or repel water. Pore fillers consist of silicates of soda, aluminum, and zinc sulfates, which are chemically active. Additionally, they speed up the setting time of concrete, which renders it more impervious at an early stage. Chalk, fuller earth, and talc are chemically inactive pore-filling materials. These materials are normally very finely ground. Basically, they make dense concrete impervious and facilitate the reduction of water for a given workability. In this group of admixtures, materials, such as soda, potash soap, calcium soap, resin, vegetable oils, fats, waxes, and coal tar residues are added as water repellants. It’s common to add calcium or ammonium stearate and calcium chloride along with inorganic salts of fatty acids in some waterproofing admixtures.

Grouting Admixtures

Depending on the conditions or purpose of grouting, different grout-mixing qualities would be needed. The grout mixture often needs to set rapidly, and sometimes it requires remaining in fluid form for a long period of time so that it can flow into the cavities and fissures of the surface. The following mixtures are used for grouting: Accelerators, Retarders, Gas Forming Agents, Workability Agents, and Plasticisers. As a result of chemical reactions, aluminum powder forms small bubbles of hydrogen, allowing the grout to expand. Consequently, settlement and shrinkage are eliminated. Flowability and durability are achieved using plasticisers and superplasticizers in powder form in the grout mixture.

Depending on the conditions or purpose of grouting, different grout-mixing qualities would be needed. The grout mixture often needs to set rapidly, and sometimes it requires remaining in fluid form for a long period of time so that it can flow into the cavities and fissures of the surface. The following mixtures are used for grouting: Accelerators, Retarders, Gas Forming Agents, Workability Agents, and Plasticisers. As a result of chemical reactions, aluminum powder forms small bubbles of hydrogen, allowing the grout to expand. Consequently, settlement and shrinkage are eliminated. Flowability and durability are achieved using plasticisers and superplasticizers in powder form in the grout mixture.

There are several common construction chemicals on the list. To enhance or modify concrete and other construction, such as Plasticisers, Superplasticisers, Retarders and Retarding Plasticisers, Pozzolanic or Mineral Admixtures, Damp-proofing and Waterproofing Admixtures, Gas forming Admixtures, Alkali-aggregate Expansion Inhibiting Admixtures, Workability Admixtures, Grouting Admixtures, Corrosion Inhibiting Admixtures, Bonding Admixtures, Germicidal, and Insecticidal Admixtures, Coloring Admixtures, Concrete Curing Compounds, Polymer Modified Mortar for Repair and Maintenance, Protective and Decorative Coatings, Installation Aids, Floor Hardeners and Dust-proofers, Surface Retarders, Bond-aid for Plastering, Construction Chemicals for Water-proofing, etc.

To put it simply, construction chemicals have played a significant role in all kinds of construction projects--be it industrial, residential, or commercial. As well as waterproofing, these chemicals enhance a variety of other important aspects, including strength, durability, and workability. The construction industry can’t function without these chemicals.

Stay updated with the latest trends and developments in architecture, design, home decor, construction technology, and building materials through Building Material Reporter.